|

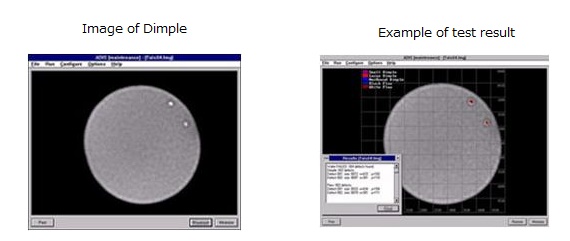

It comes with a complete set of wafer handing system with edge grip and place a wafer on the inspection stage automatically. Optional automated defect inspection software enables wafer sorting by automated inspection results of defects. Inspection categories are, dimple, mound, saw mark, non-uniform polishing marks, orange peel, SORI and others. |

■Specification

| Wafer size | 4 inch to 12 inch wafers |

| Defects type | Flatness, dimples, saw marks, Orange peel, etc. |

| Magnification | 1X to 3X |

| Sensitivity | Seamless sensitivity adjustment setting |

| Light source | 550nm (Stabilized light source) |

| Camera | High resolution CCD camera |

| Inspection stage | Manual stage (standard) |

|

|

Output of inspection results will be: Type of defect, number of defects per category and their respective positions by dialogs. |