HC-200 is an ideal UV spot curing system to cure UV Curing adhesive or UV curing ink.

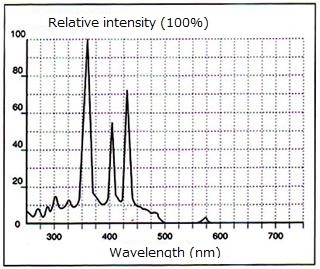

The lamp HC-200 uses is a high power Mercury-Xenon Lamp, and we cut Infrared wavelength to avoid building up heat of target under curing.

Our proprietary lamp alignment method will not require to turn the lamp on for optical alignment. It will be safe and easy to complete an lamp replacement and optical alignment in a very short time.

|

Features

|

|

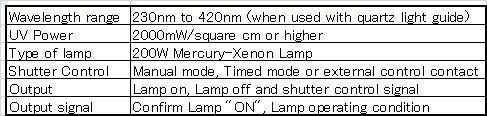

Specification

※Intensity is measured at 10mm from the end of Quartz fiber bundle with 5mm diameter, 1meter long .

※If you need a spot curing system with a different intensity level, please contact us for a custom UV curing system.。

※We can adjust output wavelength for 254nm, 313nm, 365nm, 405nm or 436nm respectively.