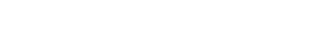

“Impact Actuator” is an electric hammer that applies a striking force to the work (object) to move it by using the inertia force of rapid expansion and contraction of the piezo-electric actuator.

The actuator can be used for fine position adjustment of components during assembly and rotation centering, etc.

| Actuator Mechanism, Actuator location |

Mechanism

The top end of the actuator is abruptly elongated in sub-milliseconds to impact an object and then quickly returns to its original position.

Actuator location

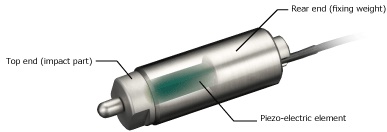

2-way adjustment

As 1 actuator works in 1 direction, locate 2 opposed actuators for traveling in both direction.

1-way adjustment

For applications such as centering adjustment while rotation, etc., use 1 actuator for adjustment.

Applications

• Positioning of temporarily tightened parts

• Centering of discs and rotary parts

• Optical axis adjustment for laser optics

• Precision press-in

• Lens centering

• Oscillation source

Line Up

| Impact Actuator |

| Controller / Driver |

A dedicated controller driver to drive the impact actuator.

The controllers and drivers for Piezo Stage cannot drive the impact actuator.

| Type | Single-axis | Multi-axes |

|---|---|---|

| Model No. | SD301 | SC1000+ST1000+SD101C |

| Appearance |

|

|

| Main features | – 1 actuator can be connected for driving – The controller and driver are housed in 1 case for space saving. – Price reasonable |

– Up to 8 actuators can be connected -Eeasily performed by using the handy terminal,and RS232C interface is also available. |

| Connectable number of actuator | 1 axis | 1~8 axes |

| Interface | External I/O | RS232C |

| Power supply | AC100V±10%, 50/60Hz | |

| Power consumption | 50VA | 62VA |

| Weight | 3kg | ST1000:0.7kg SC1000:0.8kg SD101C:5.0kg |